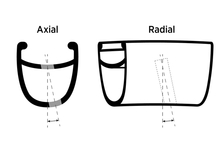

System load vs Axle load

With the increase of E-Bikes as well as Cargo Bikes, more and more attention has been brought on the load a bicycle and rims could carry. This has become a crucial topic for many bicycle producers.

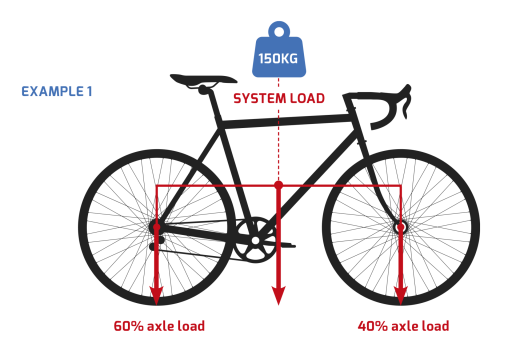

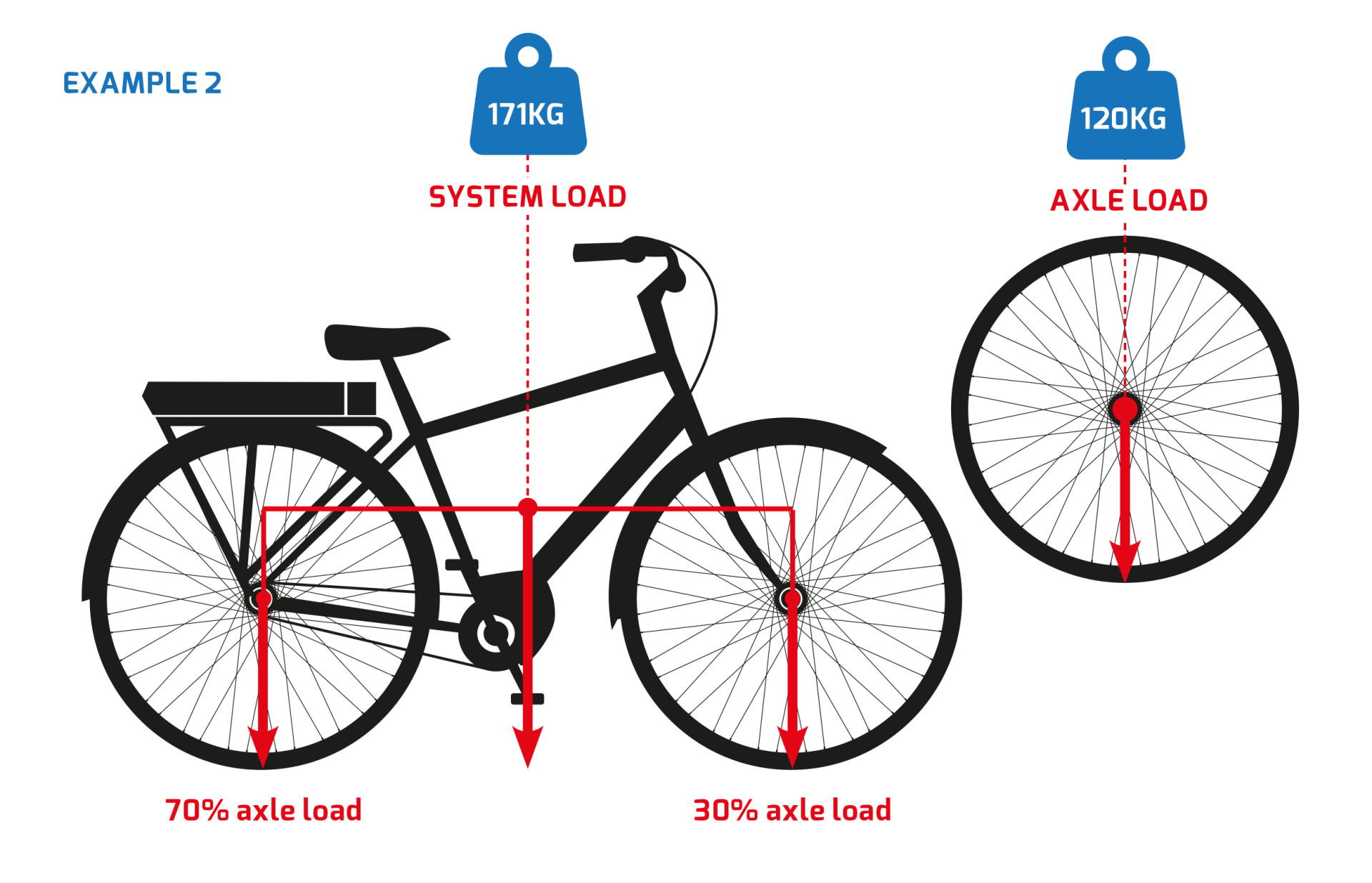

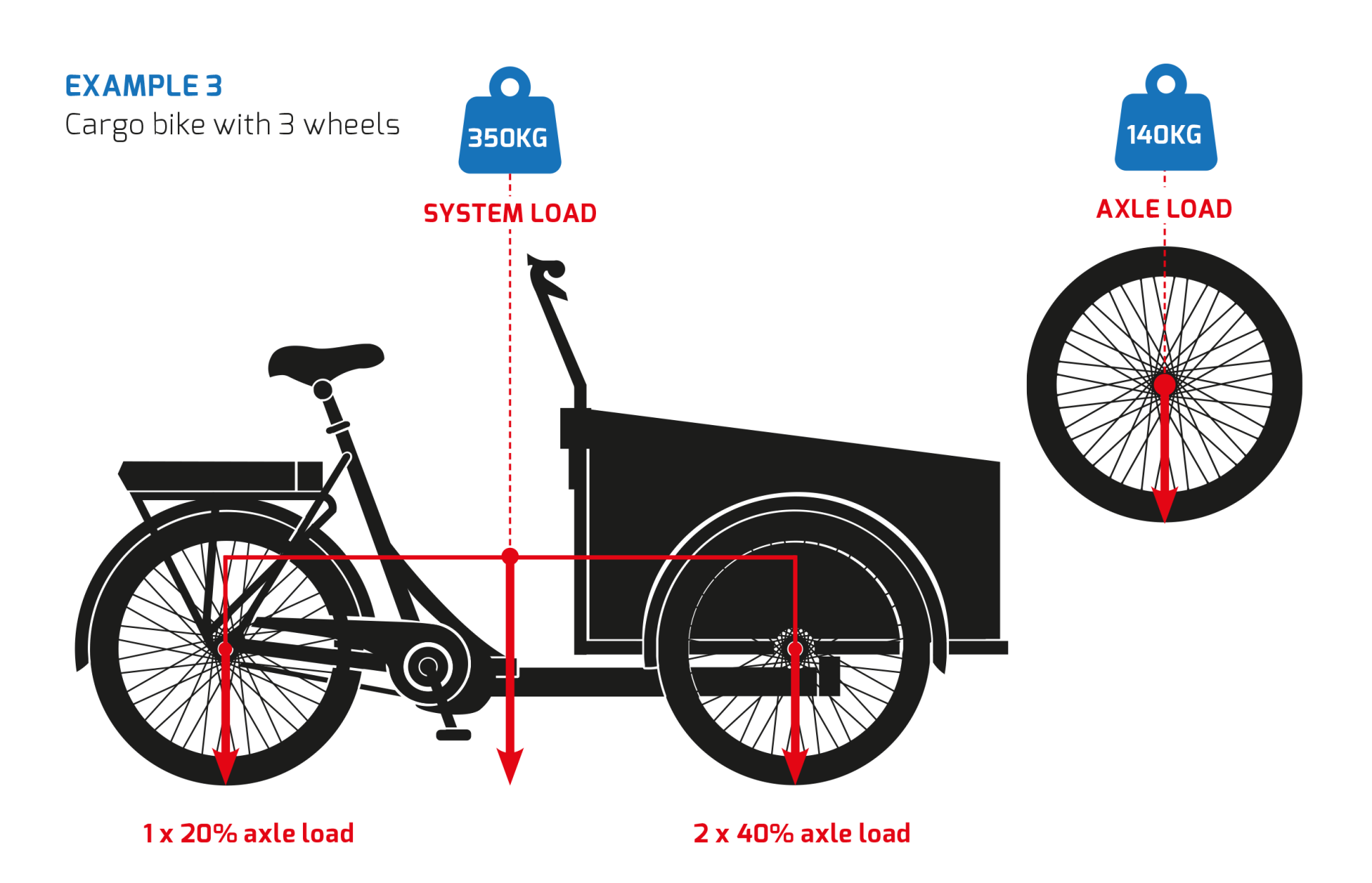

The load a bicycle can handle is measured in kilograms. However, there are two ways of measuring the load. Axle load and System load. But what is the difference between both terms?

AXLE LOAD ≠ SYSTEM LOAD

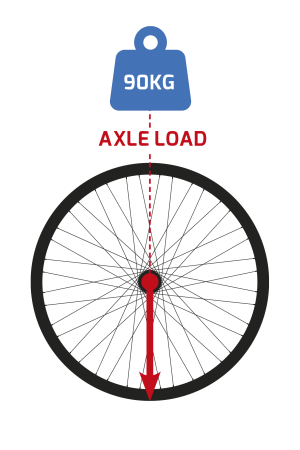

AXLE LOAD

Axle load is the maximum load, measured in kilograms, one single rim or wheel can carry.

SYSTEM LOAD

System load is the maximum load, measured in kilograms, one single bicycle or cargo bike can carry.

The strongest rim models of Ryde can handle an axle load going up to 220 kg which could be translated into a sytem load of 315 kg (assumption of 30% on the front wheel and 70% on the backwheel). However, when testing heavy loads, we come to the limitation of the weight that a tyre (aswell as an inner tyre) can carry. The heaviest load that could be carried by a tyre is 140 kg.

Ryde is committed to push the limit even higher since it already anticipates the trend and is currently working on the development of even more sophisticated rims.

To test these heavy loads, our lab tests rims and wheels according to the latest DIN 79010 Transportation & Cargo which guarantees that rims are tested according to universal ISO standard. These test loads are not confirmed from certified testing institutes.

Technologies

FLAT HOLE (FL)

Nipple holes come in different diameter as an option for 13G nipples as well. We offer 4,5mm 14G and 5,5mm 13G. Those holes are often directional drilled to improve the spoke nipple line up to a certain extent.

SINGLE EYELETS (SE)

The stainless steel material resist to corrosion. It improves the strength around nipple hole, improves nipple / rim seat and reduces the wear out of the nipples and rim.

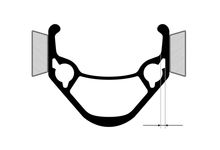

DOUBLE EYELETS (DE)

The stainless steel material of the external eyelet resists to corrosion. Together with the internal pan it improves strength of the rim by connecting the two walls of the rim. As a consequence, it distributes the spoke tension on two rim walls. The strength around nipple hole is higher. Like the SE, the DE improves the nipple / rim seat and reduces the wearing out of the nipple and rim. Wheel building a double eyelet rim is made easier since no nipple can fall in the chamber.

WASHER

Our stainless steel washers have multiple advantages. They increase the strength of the nipple hole by up to 30%. This insures also a longer fatigue life time of the wheel. The washer is formed to guide the nipple into the spoke direction and gives less friction to the nipple. A perfect equal tension is the result. The washer can slide on the flat rim bottom to give even better results. Do not use the washer offered with the

Trace series with any other rims.

INTERNAL DIMPLING (ID)

ID is a deep drilling into a reinforced nipple bed with a 90° angle for the nipple bed.The spoke holes are drilled under two angles, radial and axial for a better spoke nipple line. The V shape dimpling ads also more contact to the nipple and the deformation of the nipple is reduced. ID is a Ryde patented design

DIRECTIONAL DRILLING

Ryde pioneered the directional drilling of the spoke holes to avoid bends between the spoke and the nipple. This brings less stress on the spoke and therefore reduces the chance of breaking spokes. For trekking bikes with bigger hubs, Ryde can drill the nipple holes in some models up to 36°. Ryde rims are usually French drilled and are offered in DIN drilling as well if specially required.

ZIG ZAG

On some rim models depending on profile you can see a left and right off set of the nipple holes. This can help to have a better spoke nipple alignment. Also this makes it very visible if you have a French or Din drilling. In addition the holes in the tire bed are more centred which allows the use of a wider range of rim tapes.

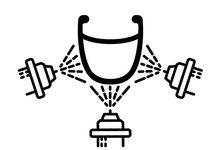

STAR ASSEMBLING TECHNOLOGY (SAT)

Ryde offers the possibility of special spoke patterns. Drilling pattern like 10 x 2 or 7 x 4 gives a unique look to the wheel. Ryde can offer a large variety of different drilling pattern. Before ordering those patterns a discussion with our wheel experts is recommended.

ULTIMATE POWER (UP)

The machined turned off side wall improve the braking performance and offers an optimal parallelism of the rim, a smooth joint and a better look.

INTERNAL SAFETY LINE

This system shows the rim wear without the risk that the rim sidewall collapses immediately without warning. The pin channel is opening up before the hook is collapsing. With the visible crack in the rim the sidewall stays with its integrity, but needs to be replaced asap. This prevents potential accidents. Internal safety line is a Ryde patented design. Safety line is offered on all UP pinned rims.

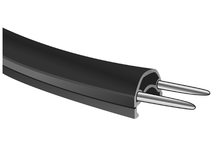

PIN JOINT

Pin joint rim offers more stability. The two channels add more weight and stiffness to the profile. Pin joint rims and Internal safety line work together in one design unit.

SLEEVE

For top quality rims Ryde sleeves and glues the rim at the joint. This technique results in a stronger and safer joint. Leaving the pin channel away the weight of the

rim is significantly reduced.

TUBELESS READY

Most High-End rims are tubeless ready. The design is suitable to work with and without tubes. The design has improved over the last years to ensure an easy mounting and a safe tire seat on the rim.

ETRTO

The added number to the profile ensures that the size tire is clearly defined. ETRTO compliant rims are state of the art and ensure a perfect tire mounting and seat, but limit new product inventions.

POWDER COATED

Powder coating is a surface treatment during which rims are painted, usually black, but can be offered in any other RAL colours. Compared to lacquering powder coating has a high scratch resistance and has no environmental impact in the production process. The layer of thickness covers completely all extrusion marks and shows only a fine shiny surface.

ANODIZATION

Anodization as chemical treatment is lighter and more scratch and impact resistant than powder coating. The anodization is done on the profile before manufacturing the rim. In addition, the surface is also hardened. Pre anodizing is offered in two colors black and silver.

SAND BLASTED

This mechanical treatment offers a satin finish of the surface. When blasting a cutting material (i.e. sand) on the surface, all extrusion marks disappear. This treatment is often a pre step of the pre anodizing process.

POLISHING

Ryde rims can also be offered with a polished surface as mechanical treatment. This time-consuming process is giving the rim eye an catching look on the bike.

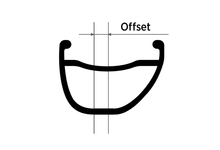

OFFSET

Many of Ryde high end rims have an asymmetrical shape where the spoke holes are not centered, but placed out of the middle of the rim. This gives a wheel a more even spoke tension between left and right and therefore a stiffer and longer lasting wheel. Offset rims have advantages with disc wheels and cassette hubs. If offset rims are not needed, Ryde supplies the same model of rim often in a symmetrical version.

AXLE LOAD

Weight applied in the axle of a single wheel. The ISO standard certifies each wheel for an Axle Load of 65kg.